11 May 2022

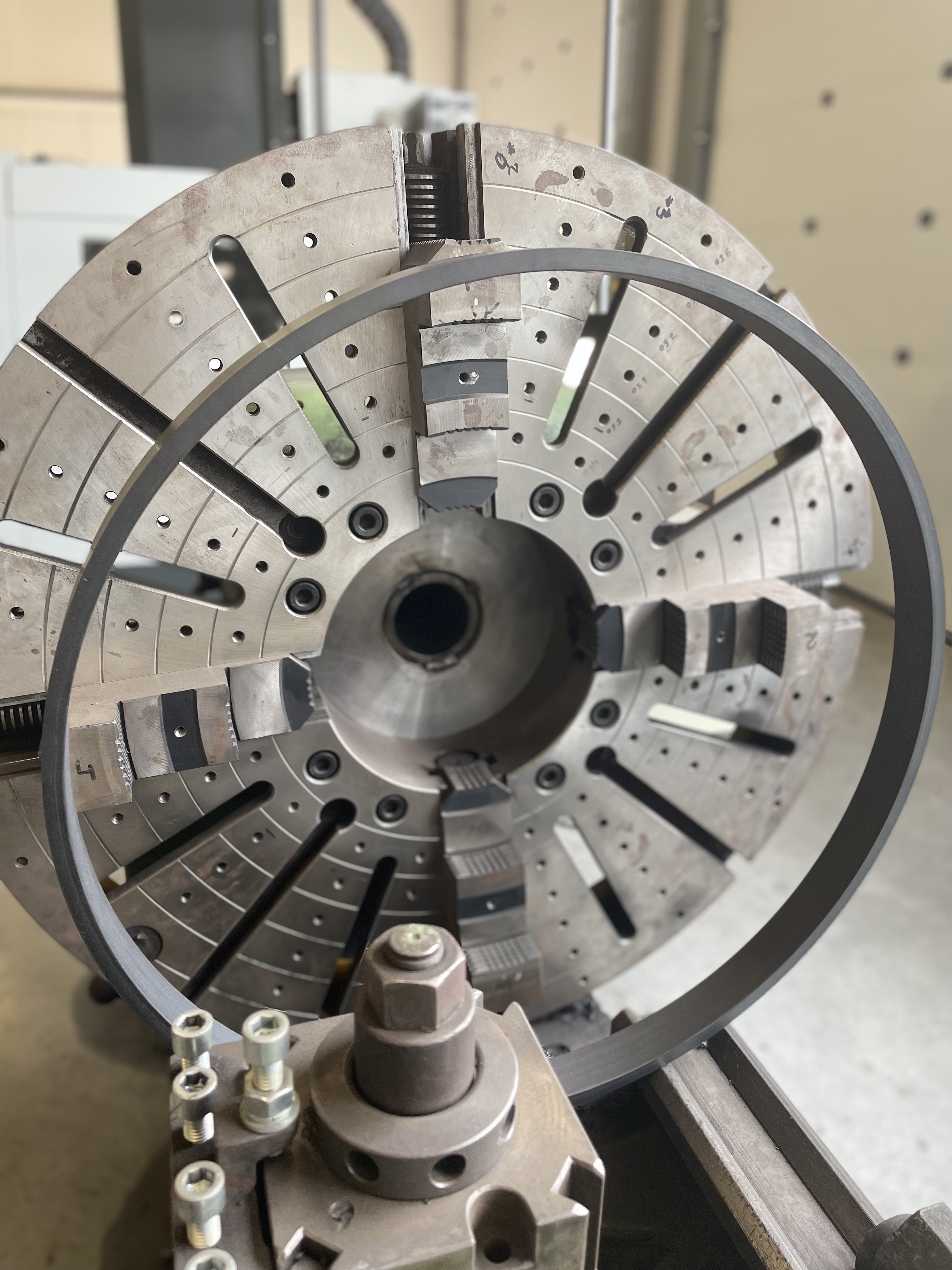

Bearing redesign of liquid gas pumps

Our customer, a well-known pump repair company, asked TENMAX to solve the problems of their end user. This Oil & Gas company faced many reliability problems with all their liquid gas pumps. The MTBF (mean time between failures) was totally unpredictable. The main problems are the use of carbon and ceramic bushings/bearings supplied by the pump OEM. After an investigation by reliability engineers they noticed that the failures in most cases started with bushing or bearing failure. As mentioned in the failure report the bearing or bushing material failed due 3 reasons ; thermoshock, dry-run problems and vibrations.

As known liquid gasses are bad lubricators and when the pump temperature rises a little or the discharge pressure drops there will be no liquid gas in the rotating parts but merely gas! Situations like this mostly occur by start or stop the pump installation, but also during running of pump curve.

They chose TENMAX TMC materials after a field test and concluded that TMC materials can handle thermoshock, can run dry and are able to resist vibrations.

Customers commentary :

“We like to work with TENMAX for their pump knowledge and redesign capabilities to change out pump materials, also they do it all: from engineering the materials to final machining.”

For more information or inquiries please contact one of our engineers here.

View Details